SIL2 status achieved for Ex-tech Signalling’s ATEX and IECEx products

23 April 2025

SIL2 status achieved for Ex-tech Signalling’s ATEX and IECEx products

Ex-tech Signalling explosion proof products featuring sounders, manual call points, beacons, push buttons and combination units, have achieved SIL2 status. This shows our commitment to manufacturing reliable, high-performance safety solutions which meet compliance standards across the globe.

What is SIL2 and why it’s important

A Safety Integrity Level (SIL) is a measure of the reliability and performance of safety systems used to reduce risk in industrial processes. It is part of the functional safety standards defined by the International Electrotechnical Commission (IEC) in standards such as IEC 61508 and IEC 61511. SIL levels are used to specify the necessary performance requirements for safety-related systems to ensure they function correctly when needed. There are four levels as defined below.

- SIL 1: Lowest level of safety integrity, with a higher probability of failure.

- SIL 2: Moderate level of safety integrity.

- SIL 3: High level of safety integrity.

- SIL 4: Highest level of safety integrity, with the lowest probability of failure.

SIL2 is commonly expected in the oil and gas industry across the world. For example on systems such as Emergency Shutdown Systems (ESD) or fire and gas detection systems that trigger alarms and sounders.

Meanwhile SIL 1 can be an acceptable level in many ATEX hazardous areas, but it is essential to conduct a detailed risk assessment to determine the appropriate SIL level for each specific application.

Ex-tech Signalling has always had SIL1 but this additional level enables us to access more applications.

How do ATEX and SIL2 relate to each other?

SIL and ATEX are both critical concepts in ensuring safety in hazardous areas, but they address different aspects of safety while complementing each other. ATEX ensures that equipment is safe to use in potentially explosive atmospheres by preventing ignition sources, while SIL ensures that safety systems are reliable and perform correctly to mitigate risks and prevent hazardous events.

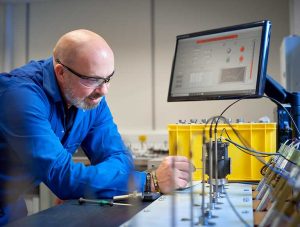

Enhanced reliability for hazardous areas

By managing the complete design and production process in-house at our UK facility, Ex-tech Signalling ensures uncompromising quality control. Each component – from initial material selection to final testing – is subject to our most exacting standards.

This level of control enables us to tailor products precisely to our customers’ demands, ensuring optimal performance in the field. Products comply with ATEX and IECEx requirements to ensure they are safe for use in potentially explosive atmospheres and can’t cause an explosion. This is very important for industries like petrochemical, energy, food and drink or waste which operate with hazardous areas where manual call points and push buttons for example, are essential for triggering an alarm. Call points such as the break glass unit shown, typically then trigger sounder devices as part of a fire alarm system which must also be ATEX compliant with a suitable SIL rating.

Robust construction and environmental resistance

The design of our audible visual signalling products anticipates the harshest operating conditions. Beyond SIL2 and ATEX/IECEx compliance, these devices are IP66/67 rated, which means protection against dust and water ingress – a crucial feature in environments constantly exposed to rain, salt spray, and corrosive elements.

We offer GRP or stainless steel options to suit different environments and operations.

Serving global markets with confidence

Achieving SIL2 status for our products including ATEX sounders unlocks new opportunities for global collaboration. Distributors and original equipment manufacturers (OEMs) in territories where SIL2 compliance is mandatory can now partner with Ex-tech Signalling when developing fire alarm systems for example. Our products meet the highest international standards, ensuring reliability and safety – ATEX, IECEx and now with SIL2.