Explosion Proof (ATEX / IECEx) Manual Call Point “Break Glass”- CP150

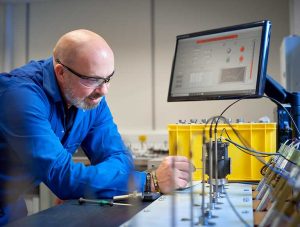

The flameproof CP150 manual call point is ATEX/IECEx certified for use in potentially explosive atmospheres, SIL2 and it can be used in conjunction with a fire alarm system and will activate alarms to alert personnel to potential dangers, help signal the need for immediate action in emergency situations and more. Also known as explosion proof fire alarm call point, manual call point (MCP) or “Break Glass” call point. Optional SIL2 IEC61508 certifications.

Key Features

- Robust and highly reliable, this Ex manual call point (MCP) / Break Glass call point is designed for corrosive environments and hazardous areas.

- SIL2 compliant according to IEC 61508 & IEC 61511.

- The housing is moulded in Glass-Reinforced Polyester (GRP), protected by an UV resistant paint.

- These ATEX / IECEx compliant manual call points / “Break Glass” call points are compatible with PLC, ESD and DCS systems.

- The Manual Call Point is supplied with a hammer and securing chain.

Zones

ATEX Zone 1 and Zone 2 Certified for group IIC gas / vapour applications and Zone 21 and Zone 22 compliant for dust / powder applications.

Applications

Oil and gas, chemical, petrochemical, pharmaceutical, marine and offshore applications.

Product Downloads

Datasheets

Download Extech CP 150 datasheetCertificates

Download Ex-tech-ATEX-13-NEMKO-1564X-CP150-1 CertificateDownload IECEX CERTIFICATE OF CONFORMITY CP150-PB150 13.0034XDownload EU DoC CP150 & PB150 Rev 5Download CP125, CP135, CP150 SIL2CAD Drawings

Download 5-cp150_asm.rar CADUser Manuals

Download Ex-tech-UM-CP150-EN User ManualWiring Diagrams

Download 2095A3 / Standard wiring – single switch – no LED – no resistors – no diodesDownload 2122A3 / Standard wiring – single switch – no LED – 1 to 2 resistors – no diodesDownload 2099A3 / Standard wiring – single switch – red & green LED – no resistors – no diodesDownload 2100A3 / Standard wiring – single switch – red & green LED – 1 to 2 resistors – no diodesDownload 2116A3 / Standard wiring – double switch – no LED – no resistor(s) – no diodeDownload 2118A3 / Standard wiring – double switch – no LED – 1 to 4 resistors – no diodesDownload 2097A3 / Standard wiring – double switch – red & green LED – no resistors – no diodesDownload 2123A3 / Standard wiring – double switch – red & green LED – 1 to 4 resistors – no diodesVisualisation functions, line detection and glass protection are optional. A range of accessories is available to customise this ATEX / IECEx manual call point. These include pipe mounting brackets, sunshades, tag and duty labels and other accessories.

- MATERIAL – Enclosure: Glass-Reinforced Polyester (GRP)

- COLOUR – RED : RAL3001/3028 • BLACK : RAL9005 • ORANGE : RAL2010 • YELLOW : RAL1018 • GREEN : RAL6032 • BLUE : RAL5005 • GREY : RAL7038

- INGRESS PROTECTION – IP66/67

- AMBIENT TEMPERATURE FOR OPERATION – T6 = – 40°C ~ + 55°C , T5 = – 40°C ~ + 60°C, T4 = – 40°C ~ + 70°C

- CERTIFICATION – Nemko 13 ATEX 1564X, IECEX NEM 13.0034X

- EX CODE – II 2 GD Ex d IIC T6 Gb • Ex tb IIIC T85°C

- STANDARD – EN / IEC 60079-0, EN / IEC 60079-1, EN / IEC 60079-31

- ATEX AREA ZONE – Gas zone: 1 & 2 Dust zone: 21 & 22

- AMBIENT HUMIDITY* – up to 95%

- RATED IMPULSE WITHSTAND VOLTAGE – 1kV following IEC 61000-4-5

- CONTACT TYPE – 1x C/O or 2x C/O

- CONVENTIONAL THERMAL COURANT (LTH) – AC 125/250 V (50/60Hz) =11A*** ; 30V DC = 6A***; 125 V DC = 0,3A***; 250 V DC = 0,6A***

- MINIMUM VOLTAGE AND COURANT – DC 5V 10mA

- SHORTS CIRCUIT PROTECTION – 10 A gG

- CABLES ENTRY – 4 x M20, 1 x M25 + 3 x M20, 1 x 1/2’’ NPT + 3 x M20, 1 x 3/4’’ NPT + 3 x M20

- TERMINAL – From 22 to 14 AWG – from 0.50 mm² to 2.5 mm²

- NET WEIGHT – 3.5 Kg

- LINE RESISTOR** – 470 Ohms** • 1 watt

- SIGNALLING LED** – Green U =24VDC I= 10 mA ; Red U=24V DC I = 20mA

* = without runoff – ** = optional – *** = resistive load – cable gland and blind plug not provided

Global Coverage & Accreditations

Where to buy?

Discover resellers of some of the most robust and reliable signalling products for hazardous areas, located across the country. Proudly made in Great Britain with the quality assurance you'd expect from a Pioneer Safety Group brand.

Part of the Pioneer Safety Group

A wide range of specialist safety services and products are delivered through six core brands. Well established and growing, the brands serve similar sectors to each other, often collaborating on projects to solve customers’ safety challenges. Learn more on the Pioneer Safety Group website.

Our consultancy business helps companies on their journey to compliance, solving complex safety challenges with audit, training, inspection and certification services.

UK designer and manufacturer of flameproof (Ex d), safe (Ex ia) and industrial switches, transmitters, and explosion relief valves.

Explosion protection for equipment operating in hazardous areas including lift trucks and engines, and much more.

Manufacturer of explosion proof enclosures, controls and components, including Ex enclosure population.

Manufacturer of explosion proof lights and lighting design for hazardous areas.

Manufacturer of ground support equipment specifically used for the maintenance of military aircraft.